Cov txheej txheem tshiab rau piston machining nrog DTH rauj

Cov txheej txheem tshiab rau piston machining nrog DTH rauj

Ua ntej, qhov teeb meem tam sim no ntawm perforator piston

Los ntawm qhov pom ntawm cov khoom thauj los ntawm lub piston, lub piston yuav tsum muaj qhov siab qhov tseeb thiab qhov chaw tiav,

kom nws muaj qhov zoo sealing nyhuv thiab hloov mus rau cov yam ntxwv ntawm high-frequency reciprocating tsab ntawv tsa suab; tib lub sijhawm,

nws yuav tsum muaj kev tsim qauv tsim nyog thiab kev kho cua sov kom zoo, kom nws tuaj yeem hloov tau lub zog cuam tshuam thiab

muaj kev tiv thaiv siab rau txhua yam puas thiab cuam tshuam tsis kam.

1 Piston force theory tsom xam

Los ntawm lub qhov rauj piston cuam tshuam me ntsis, nyob rau lub sijhawm luv luv, qhov nrawm ntawm nws txoj kev txav (qhov loj me thiab kev taw qhia) muajhloov pauv loj heev, nyob rau hauv qhov kev hloov pauv sai ntawm qhov loj thiab cov kev taw qhia ntawm txhua lub sijhawm nyob rau hauv qhov kev txiav txim ntawm cyclical hloov nyob rau hauv lub dynamic load,

Lub piston txoj kev lim tsis yog tag nrho cov yam ntxwv sib xws, qhov txav ntawm qhov loj tsis yog tag nrho cov qauv nrawm, lim thiab nrawm yog propagated.

nyob rau hauv daim ntawv ntawm kev ntxhov siab nthwv dej. Nyob rau hauv tus txheej txheem ntawm kev cuam tshuam rotary drilling, lub submerged rauj siv qhov cuam tshuam ntawm lub piston kom xa cov kev ntxhov siab.

yoj mus rau lub pob zeb hauv qab ntawm lub qhov los ntawm kev xyaum me ntsis kom paub txog pob zeb tawg drilling. Lub piston ntawm submerged rauj muaj qhov sib txawv

cross-section qauv, nyob rau hauv uas cov kev ntxhov siab yoj propagates thiab yog khi rau transreflected nyob rau hauv lub cross-section hloov, tsis tsuas yog nyob rau hauv lub kawg ntawm rauj.

Thaum ib qho sib npaug-section rauj raug rau kev ntxhov siab, qhov sib txawv-section rauj tsis yog tsuas yog compressive stresses, tab sis kuj rau tensile stresses.

2 cuam tshuam piston manufacturing thiab kev kho cua sov txheej txheem

Kev cuam tshuam piston kev ua tau zoo yog ze rau nws cov txheej txheem tsim khoom. Cov khoom sib txawv, nws cov txheej txheem tsim khoom sib txawv.

(1) siab carbon vanadium hlau (xws li T10V) tsim piston txheej txheem rau raw khoom tshuaj xyuas

(chemical muaj pes tsawg leeg, micro, non-metallic inclusions thiab hardenability) → khoom → forging → tshav kub kho → tshuaj xyuas → sib tsoo.

(2) 20CrMo steel manufacturing piston txheej txheem rau forging → normalizing → soj ntsuam → machining → tshav kub kho → sandblasting → soj ntsuam → sib tsoo.

(3) 35C Mr oV steel manufacturing piston txheej txheem rau forging → tshav kub kho y tshuaj xyuas (hardness) → machining → carburizing → tshuaj xyuas (carburized txheej)

→ kub kub tempering → quenching → tu → tsis tshua muaj kub tempering → xuab zeb blasting → tshuaj ntsuam → sib tsoo.

3 Piston tsis ua haujlwm tshwm sim

Piston yog ib tug complex quab yuam nyob rau hauv lub submerged rauj, yooj yim rau puas qhov chaw. Piston nyob rau hauv high-pressure gas tsav, nrog rau kev kub ceev cuam tshuam me ntsis, thiab ces dhau

lub ntsis mus rau hauv qab ntawm lub pob zeb cuam tshuam lub zog hloov. Cov txheej txheem cuam tshuam, lub piston los ntawm qhov loj thiab kev taw qhia ntawm lub zog yog rau kev hloov pauv raws sijhawm, txog 100 thoob

s nyob rau hauv lub zog dheev nce mus rau kaum ob tons, los yog ntau dua, thiab tom qab ob peb puas microseconds, thiab ces rov qab mus rau xoom. Ntev ntev raug rau

rov ua qhov cuam tshuam tam sim ntawd, yuav ua rau muaj kev ntxhov siab nyob hauv qee qhov ntawm lub piston, ua rau piston puas tsuaj, qhov kev puas tsuaj no tshwm sim hauv kev tsim kho.

Kev ua haujlwm ntawm cov tshuab cuam tshuam, kom lub piston tsis ua haujlwm, xws li: piston tawg, piston taub hau kev nyuaj siab, piston taub hau hlau spalling.

Thaum pib ntawm cov txheej txheem xeem, lub neej ua haujlwm ntawm lub qhov rauj piston yog qhov tsawg heev, ntau tshaj ib qho tawg, yuav luag txhua qhov tawg yog nyob rau hauv txoj kab uas hla me me.

qhov chaw ntawm lub piston, qee qhov muaj longitudinalcov kab nrib pleb ncaj nraim mus rau qhov kawg ntawm txoj kab me me, Daim duab 2 rau qhov tawg ntawm lub piston ntawm daim duab lub cev. Lub neej ua haujlwm ntawm lub

piston yuav cuam tshuam ncaj qha rau kev ua tau zoo ntawm submerged rauj nws tus kheej thiab kev txhawb nqa thiab kev siv ntawm kev nkag mus rau hauv submerged rauj drilling tshuab, thiab

vim li cas rau nws cov pob txha yuav tsum tau soj ntsuam los ntawm lub xeev tshwj xeeb quab yuam ntawm lub piston.

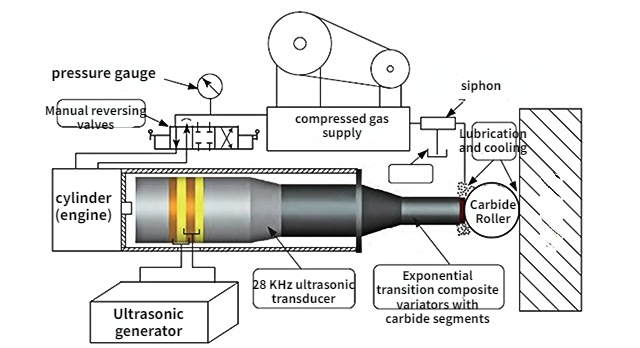

Thib ob, cov txheej txheem tshiab ntawm submariner piston machining

Cov khoom

HFD Mining Tools yog ib lub lag luam raws li kev ywj pheej innovation, uas tau cog lus los txhim kho qhov hnav tsis kam thiab kev pabcuam lub neej ntawm DTH cov khoom thiab rauj.

HFD Mining Tools tau ua tiav cov khoom tseem ceeb ntawm DTH rauj.

1 、 Cov Cai Khoom

Hlau nto siv lead ua remodeling TM thev naus laus zis yog kev hloov pauv tshiab hauv kev siv tshuab hlau ntog los ntawm kev xav ntawm daim iav ua, siv lead ua

remodeling, txheej txheem ntawm kev tshawb fawb, tshem tawm cov crystal defects ntawm cov hlau nto. SPIRIT's Crystal ResurfacingTM thev naus laus zis tuaj yeem txo qhov chaw zoo heev

roughness thiab txhim kho qaug zog lub zog, microhardness, abrasion kuj, corrosion kuj thiab lwm yam khoom ntawm hlau nto. Nws zoo heev txhim kho kev pabcuam

Lub neej ntawm DTH Hammers.

2, DTH hammers piston hlau nto ua rau muaj kev cuam tshuam:

1) Cov hlau saum npoo tuaj yeem yooj yim paub cov nyhuv iav, Ra≤0.2μm.

2) Hlau nto crystal remodeling, grain refinement.

3) Surface microhardness nce 10% -30%.

4) Tshem tawm cov khoom siv lead ua tsis xws luag thiab tsim kom muaj kev ntxhov siab ntawm cov hlau nto.

5) Txhim kho qhov hnav tsis kam thiab corrosion kuj ntawm hlau nto.

6) Qhov tseem ceeb nce lub neej ncua sij hawm ntawm qhov chaw rau kev pab cuam ntawm kev ua haujlwm.