- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

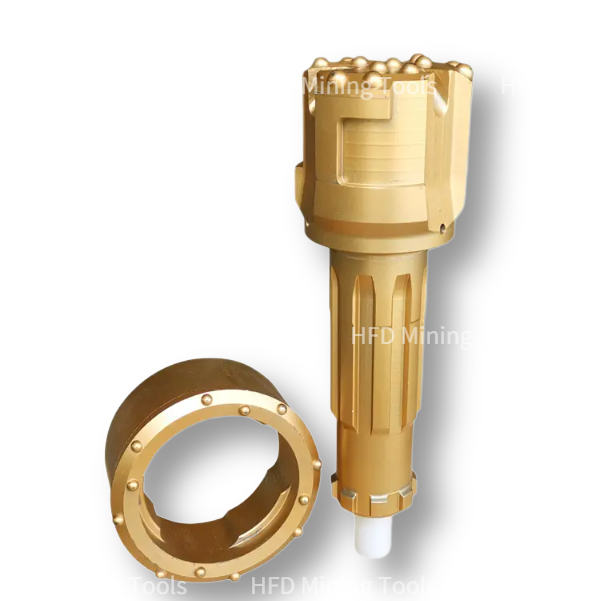

Concentric/Symmetric Casing overburden Drilling System with Ring Bit

Type:Concentric System

Processing Type:Forging

Advantage:Easy to lock and unlock

Brand: HFD Mining Tools

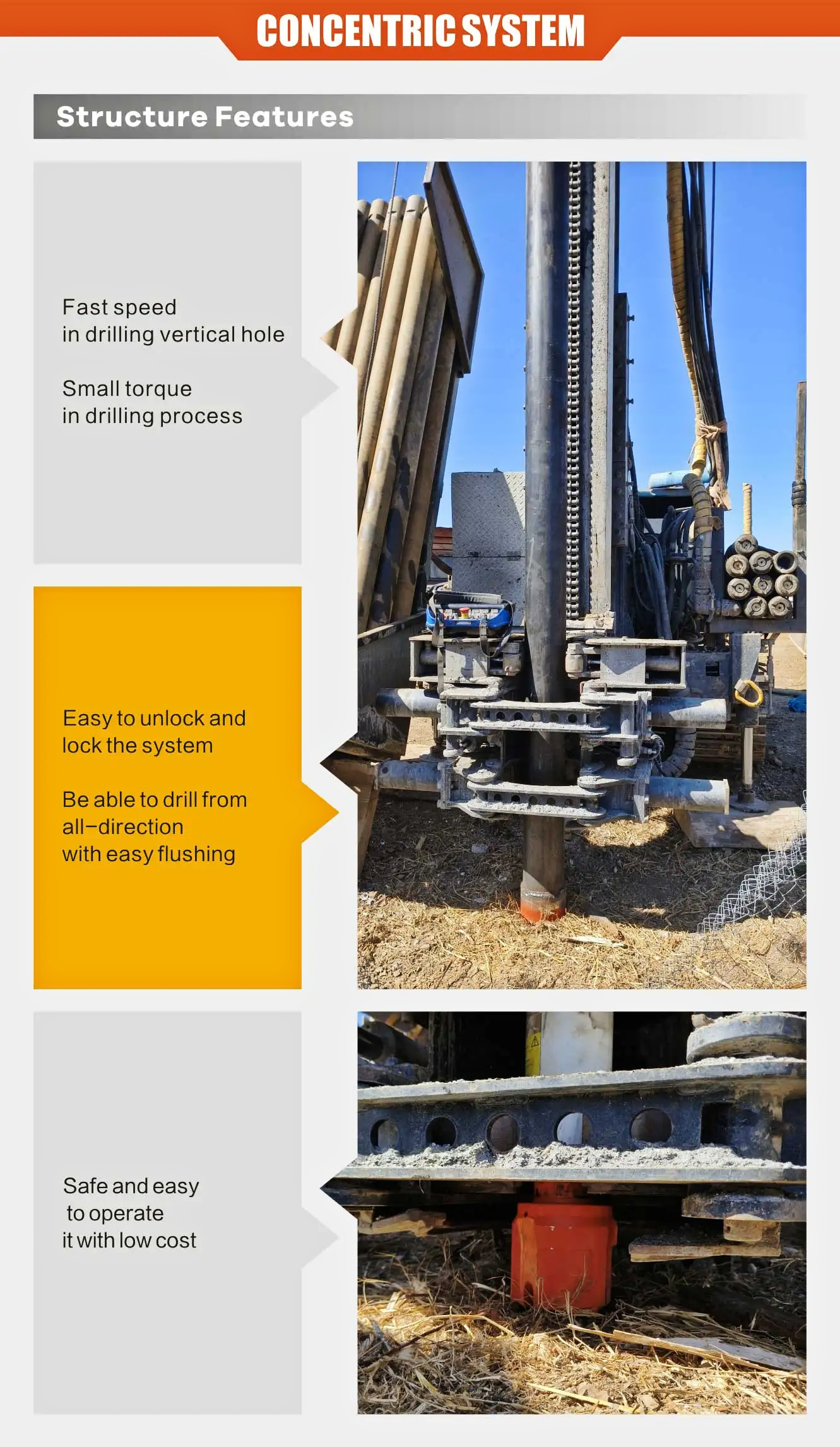

01 Drilling Staight and fast 02 The torque for concentric drilling is much less than for eccentric dirlling. 03 Easily Unlocking-relocking 04 Drilling in any angle. 05 Effective cuttings discharge. 06 Easy-to-operate and system security. 07 Economical and cost-effective.

د تفصيلي معلوماتو لپاره د نرخ غوښتنه وکړئ (MOQ، نرخ، تحویلي)

Concentric/Symmetric Casing overburden Drilling System with Ring Bit :

|  |

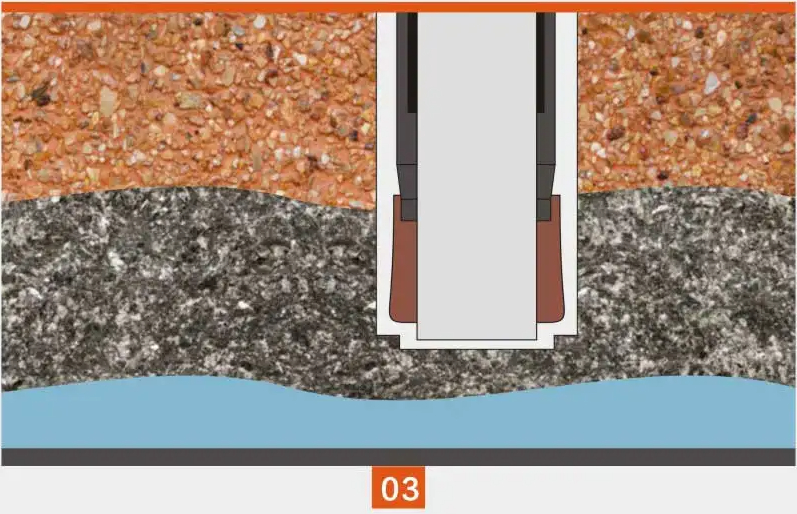

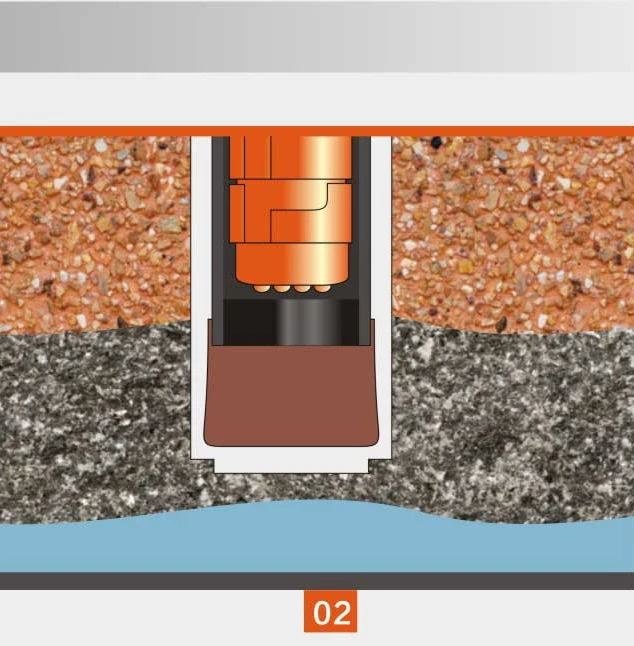

| When starts drilling,weld casing tube with ring bit,then lock pilot bit with the ring bit so that the shoulder of pilot bit is perfectly matched with the casing shoe. When impact power transmits to pilot bit and ring bit, the system starts to break rock, bringing down casing tube. | When casing tube is installed until bedrock,reversely turn the pilot bit and pull out from the hole, keeping ring bit and casing tube stay in the hole.Anyway the ring bit and casing tube can be pulled out from the hole if doing grouting at the same time. |

| |

| if need to drill a deeper hole when casing tube is stalled until bedrock,pull out pilot bit from the hole and change a conventional rock bit to continue to drill until desired depth is reached. | |

For more specifications, please contact us and accept the customized size;

| Model | Casing Tube O.D | Bit Diameter (Button Included) | Casing Shoe I.D | Maximum Reaming O.D | Hammer Style | |

| 146 | ¢146 | ¢123.5 | ¢116 | ¢156 | 4 |

| 168 | ¢168 | ¢146 | ¢140 | ¢184 | 5 | |

| 178 | ¢178 | ¢157 | ¢150 | ¢194 | 5 | |

| 183 | ¢183 | ¢160 | ¢152 | ¢198 | 5 | |

| 194 | ¢194 | ¢178 | ¢164 | ¢208 | 6 | |

219 | ¢219 | ¢203 | ¢192 | ¢234 | 6-7 | |

| 245 | ¢245 | ¢217 | ¢205 | ¢260 | 6-8 | |

| 273 | ¢273 | ¢246 | ¢233 | ¢291 | 8 | |

| 325 | ¢325 | ¢297 | ¢282 | ¢340 | 8-10 | |

| 377 | ¢377 | ¢351 | ¢332 | ¢405 | 10-12 |

Why Choose HFD Down the hole bits ?

In the top hammer drilling tool manufacturing, we have world-class production technology, advanced production equipment, and experienced production technical staff. We have been working closely with our customers to conduct extensive on-site tests on various types of rocks and working conditions. Based on the feedback, we continue to improve and develop in various areas such as raw materials, heat treatment, design and manufacturing processes.

In terms of product consultation and rock tool services, we can select the most suitable rock drill tools and drilling construction schemes according to the user's construction conditions, rock type, mineral conditions and drilling equipment, so as to help users improve drilling efficiency, reduce drilling costs, and achieve better comprehensive benefits and higher labour productivity.

Our Down the hole bits have a good industry reputation in mining, tunnelling, quarrying, roads or construction due to their excellent wear resistance, roughening resistance and stability. Compared with many world-class brands of drilling tools, our rock drill tools are not inferior. In some field comparison tests, the use efficiency of our many products even exceeds that of world-class brands and has been highly recognized by customers.

Service & Support

Every purchase comes with round-the-clock after-sales service, support, and training to ensure customers get maximum productivity from their drilling operations. Having a knowledgeable and technical partner, on-site or online, can make the difference between going it alone and leveraging experience and expertise. Customers can rely on our service and support, which are provided by cost-effective and professional DTH drilling tool manufacturers. We know about downhole drilling!