Ts'ebetso e ncha ea mochini oa piston ka hamore ea DTH

Ts'ebetso e ncha ea mochini oa piston ka hamore ea DTH

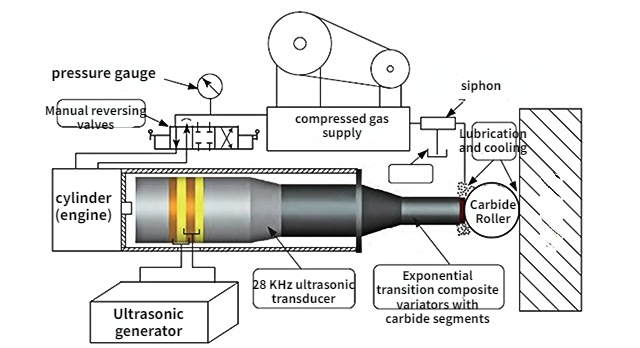

Ntlha ea pele, boemo ba hona joale ba piston ea perforator

Ho ea ka pono ea mojaro o jereng piston, piston e hloka ho ba le ho nepahala ha maemo a holimo le pheletso ea bokaholimo,

e le hore e be le phello e ntle ea ho tiisa le ho ikamahanya le litšoaneleho tsa ts'ebetso e phahameng ea maqhubu a holimo; ka nako e tšoanang,

e hloka ho ba le moralo o nepahetseng oa sebopeho le kalafo e ntle ea mocheso, e le hore e ka fetisa matla a tšusumetso le

e na le khanyetso e phahameng ea abrasion ea mechine le ho hanyetsa tšusumetso.

1 Piston force theory analysis

Ka nako e khuts'oane haholo, lebelo la motsamao oa eona (boholo le tataiso)e fetohile haholo, ka liphetoho tse potlakileng tsa boholo le tataiso ea nako eohle tlas'a ketso ea liphetoho tsa cyclical mojaro o matla,

mofuta oa piston ha se mofuta o akaretsang oa mofuta, motsamao oa boima ha se lebelo le akaretsang, khatello le lebelo li phatlalatsoa.

ka sebopeho sa maqhubu a kgatello ya maikutlo. Ts'ebetsong ea ho cheka rotary, hamore e ka tlas'a metsi e sebelisa tšusumetso ea piston ho fetisa khatello ea maikutlo.

tsoka lefikeng le tlase ho lesoba ho elelloa ho phunya lejoe. Piston ea hamore e ka tlas'a metsi e na le phetoho

sebopeho sa li-cross-section, moo leqhubu la khatello ea kelello le atisang ho ata 'me le tlamehile ho fetisoa ka phetoho ea karolo ea sefapano, eseng feela lipheletsong tsa hamore.

Le hoja hamore ea karolo e lekanang e tlas'a khatello ea khatello, hamore ea karolo e fapaneng ha e be tlas'a khatello ea khatello feela, empa hape le khatello ea maikutlo.

2 ts'ebetso ea ho etsa piston le ts'ebetso ea kalafo ea mocheso

Ts'ebetso ea piston ea phello e amana haholo le ts'ebetso ea eona ea tlhahiso. Lisebelisoa tse fapaneng, ts'ebetso ea eona ea tlhahiso e fapane.

(1) tšepe e phahameng ea carbon vanadium (joalo ka T10V) tsela ea ho etsa piston bakeng sa tlhahlobo ea thepa e tala.

(lik'hemik'hale tsa lik'hemik'hale, li-micro, li-non-metallic inclusions le ho thatafala) → thepa → ho theha → phekolo ea mocheso → ho hlahloba → ho sila.

( 2) 20CrMo tšepe ea ho etsa piston tsela ea ho forging → normalizing → tlhahlobo → machining → mocheso oa mocheso → sandblasting → tlhahlobo → ho sila.

( 3) 35C Mr oV steel production piston process process for forging → kalafo ea mocheso y tlhahlobo (thata ) → machining → carburizing → tlhahlobo (carburized layer)

→ mocheso o phahameng oa mocheso → ho tima → ho hloekisa → mocheso o tlase oa mocheso → ho phatloha ha lehlabathe → tlhahlobo → ho sila.

3 Ketsahalo ea ho hloleha ha piston

Piston ke matla a rarahaneng ka har'a hamore e ka tlas'a metsi, ho bonolo ho senya likarolo. Piston koloing ea khase e nang le khatello e phahameng, e nang le lebelo le phahameng, ebe e feta

karoloana ho isa tlase ho lesoba la lefika le ama phetiso ea matla. Ts'ebetso ea tšusumetso, piston ka boholo le tataiso ea matla ke bakeng sa liphetoho tsa nako le nako, linkho tse ka bang 100.

s ka har'a matla a ile a eketseha ka tšohanyetso ho lithane tse ngata, kapa ho feta, 'me ka mor'a makholo a seng makae a microseconds, ebe a khutlela ho zero. Ho pepesetsoa nako e telele ho

matla a ts'ebetso a pheta-phetoang hang-hang, a tla hlahisa khatello ea maikutlo likarolong tse ling tsa piston, e leng se bakang tšenyo ea piston, tšenyo ena e tloaelehile mohahong.

ts'ebetso ea mochini oa tšusumetso, e le hore ho hloleha ha piston, joalo ka: ho robeha ha piston, khatello ea maikutlo ea hlooho ea piston, ho phatloha ha tšepe ea hlooho ea piston.

Qalong ea ts'ebetso ea tlhahlobo, bophelo bo sebetsang ba piston ea hamore ea lesoba bo tlase haholo, ho robeha ho fetang e le 'ngoe, hoo e batlang e le fracture e' ngoe le e 'ngoe e bophara bo nyane.

likarolo tsa piston, tse ling li na le longitudinalmapetsong a otlolohileng ho ea qetellong ea bophara bo bonyenyane, Setšoantšo sa 2 bakeng sa ho robeha ha piston ea setšoantšo sa 'mele. Bophelo bo sebetsang ba

piston e tla ama ka kotloloho ts'ebetso ea hamore e qoelitsoeng ka metsing ka boeona le khothatso le ts'ebeliso ea theknoloji ea ho cheka hamore e ka tlas'a metsi, le

mabaka a ho robeha ha eona a lokela ho hlahlojoa ho tloha boemong bo khethehileng ba matla a piston.

Ea bobeli, ts'ebetso e ncha ea machining ea "submariner piston".

Lihlahisoa

HFD Mining Tools ke khoebo e ipapisitseng le boqapi bo ikemetseng, bo ikemiselitseng ho ntlafatsa ts'ebetso ea ho hanyetsa le bophelo ba ts'ebeletso ea li-bits le lihamore tsa DTH.

HFD Mining Tools e atlehile ho hlahisa likarolo tsa mantlha tsa lihamore tsa DTH.

1、Molao-motheo oa Sehlahisoa

Theknoloji ea Metal surface crystal remodeling TM ke phetoho e ncha ea theknoloji ea ho sebetsa holim'a tšepe ho tloha ponong ea ho sebetsa seipone, kristale.

ho nchafatsa, mokhoa oa ho etsa lipatlisiso, ho felisoa ha mefokolo ea kristale holim'a tšepe. Theknoloji ea SPIRIT ea Crystal ResurfacingTM e ka fokotsa bokaholimo ka mokhoa o makatsang

kaba le ho ntlafatsa mokhathala matla, microhardness, abrasion resistance, corrosion resistance and other properties of metal surfaces. E ntlafatsa haholo tšebeletso

bophelo ba DTH Hammers.

2 、 DTH lihamore tsa tšepe tsa piston li hlahisa litlamorao tse tšeletseng:

1) Sebaka sa tšepe se ka lemoha habonolo phello ea seipone, Ra≤0.2μm.

2) Ho lokisoa ha kristale holim'a tšepe, ntlafatso ea lijo-thollo.

3) Bokaholimo ba microhardness bo eketsehile ka 10% -30%.

4) Ho felisoa ha liphoso tsa kristale le ho thehoa ha khatello ea khatello holim'a tšepe.

5) Ho ntlafatsa haholo ho hanyetsa ho roala le ho hanyetsa kutu ea bokaholimo ba tšepe.

6) Eketsa haholo nako ea bophelo ea likarolo bakeng sa phomolo ea mosebetsi.