Inkqubo entsha yomatshini wepiston ngesando se-DTH

Inkqubo entsha yomatshini wepiston ngesando se-DTH

Okokuqala, imeko yangoku yepiston ye-perforator

Ukusuka kwindawo yokujonga umthwalo othwelwe yipiston, ipiston kufuneka ibe nokuchaneka okuphezulu kunye nokugqitywa komphezulu,

ukwenzela ukuba ibe nesiphumo esihle sokutywinwa kwaye ivumelane neempawu ze-high-frequency reciprocating motion; ngaxeshanye,

kufuneka ibe noyilo olufanelekileyo lwesakhiwo kunye nonyango olulungileyo lobushushu, ukuze ikwazi ukuhambisa ngokufanelekileyo amandla empembelelo kunye

inokumelana okuphezulu kwi-abrasion yomatshini kunye nokumelana nempembelelo.

1 Uhlalutyo lwethiyori yokunyanzeliswa kwepiston

Umngxuma wehammer piston impact bit, ngexesha elifutshane kakhulu, isantya sokuhamba kwayo (ubungakanani kunye nesalathiso)itshintshe kakhulu, kutshintsho olukhawulezayo kubungakanani kunye nesalathiso salo lonke ixesha phantsi kotshintsho olujikelezayo kumthwalo oguqukayo,

I-piston's strain ayilulo lonke uhlobo olufanayo, ukuhamba kobunzima akusiyo isantya esilinganayo, ubunzima kunye nesantya ziyasasazwa.

ngendlela yamaza oxinzelelo. Kwinkqubo yokomba ojikelezayo, isando esintywiliselweyo sisebenzisa impembelelo yepiston ukuhambisa uxinzelelo.

phakamisa isandla uye etyeni elisezantsi komngxuma kwintwana yokomba ukuze uqonde ukugrunjwa kwamatye. Ipiston yehamile ephantsi kwamanzi inoguquko

isakhiwo se-cross-section, apho i-wave wave yoxinzelelo isasazeka kwaye ibopheleleke ukuba iguqulelwe kwinguqu ye-cross-section, kungekhona kuphela ekupheleni kwesando.

Ngelixa isando secandelo elilinganayo siphantsi koxinzelelo loxinzelelo, isando secandelo eliguquguqukayo asixhomekekanga kuphela kuxinzelelo loxinzelelo, kodwa nakwixinzelelo loxinzelelo.

I-2 yempembelelo yokwenziwa kwepiston kunye nenkqubo yonyango lokushisa

Ukusebenza kwepiston yempembelelo inxulumene kakhulu nenkqubo yokuvelisa. Izinto ezahlukeneyo, inkqubo yokuvelisa ihlukile.

(1) intsimbi ephezulu ye-carbon vanadium (efana ne-T10V) yokuvelisa indlela yepiston yokwenziwa kokuhlolwa kwemathiriyeli ekrwada.

(ukwakheka kweekhemikhali, i-micro, i-non-metallic inclusions kunye nokuqina) → imathiriyeli → ukubumba → unyango lobushushu → ukuhlola → ukucola.

( 2) 20CrMo intsimbi yokwenziwa kwepiston indlela yenkqubo yokubumba → ukwenziwa kwesiqhelo → uhlolo → umatshini → unyango lobushushu → ukuqhunyiswa kwesanti → ukuhlola → ukucola.

( 3) 35C Mnu oV umzila wepiston wokwenziwa kwentsimbi yokubumba → unyango lobushushu y ukuhlolwa (ubulukhuni ) → umatshini → ukungcwatywa → ukuhlola (i-carburized layer)

→ ubushushu obuphezulu → ukucima → ukucoca → ubushushu obuphantsi → ukuqhushumba kwesanti → ukuhlola → ukucola.

3 Ukusilela kwepiston

I-Piston ingamandla antsonkothileyo ngaphakathi kwehamile entywiliselweyo, kulula ukonakalisa iindawo. I-piston kwi-high-pressure gas drive, kunye nesantya esiphezulu sempembelelo, kwaye emva koko

isuntswana ukuya ezantsi umngxuma rock impembelelo ukudluliselwa amandla. Inkqubo yempembelelo, ipiston ngokobukhulu kunye nesalathiso samandla zezotshintsho lwamaxesha ngamaxesha, malunga ne-emele ye-100.

s ngaphakathi kwamandla anyuke ngesiquphe ukuya kwishumi leetoni, okanye nangaphezulu, kwaye emva kwamakhulu ambalwa amasekhondi ama-microseconds, aze abuyele ezantsi ku-zero. Uvezo lwexesha elide kwi

impembelelo ephindaphindiweyo yamandla efuthe ngokukhawuleza, iya kuvelisa uxinzelelo lwengqondo kwamanye amacandelo episton, okukhokelela kumonakalo wepiston, lo monakalo uxhaphakile ekwakhiweni.

ukusebenza koomatshini bempembelelo, ukuze ukusilela kwepiston, okunje: ukuphuka kwepiston, ukudakumba kwentloko yepiston, ukubola kwentsimbi yepiston.

Ekuqaleni kwenkqubo yovavanyo, ubomi bokusebenza kwepiston ye-hammer piston buphantsi kakhulu, ngaphezu kokwaphuka kwesinye, phantse yonke ifracture ikububanzi obuncinci.

iindawo zepiston, ezinye zinelongitudinalukuqhekeka ngokuthe tye ukuya ekupheleni kobubanzi obuncinci, uMzobo 2 wokuqhekeka kwepiston yomfanekiso womzimba. Ubomi bokusebenza kwe

ipiston iya kuchaphazela ngokuthe ngqo ukusebenza kwehamile entywiliselweyo ngokwayo kunye nokukhuthaza kunye nokusetyenziswa kobuchwephesha bokugrumba isando esintywilisiweyo, kunye

izizathu zokuqhekeka kwayo kufuneka zihlalutywe ukusuka kwimeko ekhethekileyo yamandla episton.

Okwesibini, inkqubo entsha ye-submariner piston machining

Iimveliso

I-HFD Mining Tools yinkampani esekelwe kwi-innovation ezimeleyo, ezinikele ekuphuculeni ukuxhatshazwa kokugqoka kunye nobomi benkonzo yeebhithi ze-DTH kunye neehamile.

I-HFD Mining Tools iphuhlise ngempumelelo amacandelo angundoqo eehamile ze-DTH.

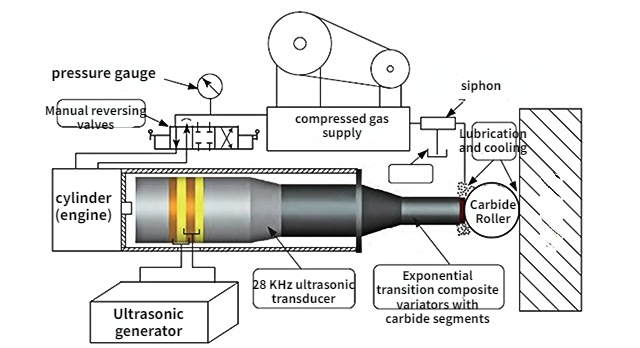

1, Umgaqo weMveliso

Itekhnoloji ye-Metal surface crystal remodeling ye-TM yinkqubo yotshintsho kwitekhnoloji yokulungiswa komphezulu wesinyithi ngokwembono yesipili, ikristale.

ukulungiswa kwakhona, inkqubo yophando, ukupheliswa kweziphene zekristale kumphezulu wesinyithi. I-teknoloji ye-Crystal Resurfacing TM ye-SPIRIT inokunciphisa kakhulu indawo

uburhabaxa kunye nokuphucula amandla okudinwa, ubuncinci, ukunganyangeki kwe-abrasion, ukumelana nokugqwala kunye nezinye iipropathi zemiphezulu yesinyithi. Iphucula kakhulu inkonzo

ubomi beDTH Hammers.

I-2, i-DTH ihamile yepiston yentsimbi ivelisa iziphumo ezintandathu:

1) Umphezulu wesinyithi unokuqonda ngokulula umphumo wesibuko, Ra≤0.2μm.

2) Ukulungiswa kwekristale yentsimbi, ukulungiswa kweenkozo.

I-3) Ubulukhuni be-Surface microhardness bunyuke nge-10% -30%.

I-4) Ukupheliswa kweziphene ze-crystal kunye nokubunjwa koxinzelelo oluxinzelelekileyo kwindawo yesinyithi.

5) Ukuphucula kakhulu ukuxhatshazwa kokugqoka kunye nokuxhatshazwa kwe-corrosion of metal surface.

6) Yandisa ngokuphawulekayo ubude bobomi bamalungu ukwenzela ukukhululeka emsebenzini.