New process for piston machining with DTH hammer

New process for piston machining with DTH hammer

First, the current situation of the perforator piston

From the point of view of the load borne by the piston, the piston needs to have high dimensional accuracy and surface finish,

so that it has a good sealing effect and adapt to the characteristics of high-frequency reciprocating motion; at the same time,

it needs to have a reasonable structural design and good heat treatment, so that it can efficiently transfer the impact energy and

has a high resistance to mechanical abrasion and impact resistance.

1 Piston force theory analysis

Through-hole hammer piston impact bit, in a very short period of time, the speed of its movement (size and direction) has changed dramatically, in the rapid changes in the size and direction of all the time under the action of cyclical changes in the dynamic load,

the piston's strain is not the overall uniform strain, the movement of the mass is not the overall uniform speed, strain and speed are propagated

in the form of stress waves. In the process of impact rotary drilling, the submerged hammer utilizes the impact of the piston to transmit the stress

wave to the rock at the bottom of the hole through the drill bit to realize rock breaking drilling. The piston of the submerged hammer has a variable

cross-section structure, in which the stress wave propagates and is bound to be transreflected at the cross-section change, not only at the ends of the hammer.

While an equal-section hammer is subjected to compressive stresses, a variable-section hammer is subjected not only to compressive stresses, but also to tensile stresses.

2 impact piston manufacturing and heat treatment process

Impact piston performance is closely related to its manufacturing process. Different materials, its manufacturing process is different.

( 1) high carbon vanadium steel (such as T10V) manufacturing piston process route for raw materials inspection

(chemical composition, micro, non-metallic inclusions and hardenability) → material → forging → heat treatment → inspection → grinding.

( 2) 20CrMo steel manufacturing piston process route for forging → normalizing → inspection → machining → heat treatment → sandblasting → inspection → grinding.

( 3) 35C Mr oV steel manufacturing piston process route for forging → heat treatment y inspection ( hardness ) → machining → carburizing → inspection ( carburized layer )

→ high temperature tempering → quenching → cleaning → low temperature tempering → sand blasting → inspection → grinding.

3 Piston failure phenomenon

Piston is a complex force within the submerged hammer, easy to damage parts. Piston in the high-pressure gas drive, with a high speed impact bit, and then through

the bit to the bottom of the hole rock impact energy transfer. Impact process, the piston by the size and direction of the force are for periodic changes, about 100 bucket

s within the force suddenly increased to dozens of tons, or even greater, and then after a few hundred microseconds, and then back down to zero. Long-term exposure to

repeated instantaneous impact force, will produce stress concentration in some sections of the piston, resulting in piston damage, this damage is common in the construction

operations of impact machinery, so that the piston failure, such as: piston fracture, piston head depression, piston head metal spalling.

In the beginning of the test process, the working life of the through-hole hammer piston are very low, more than one fracture, almost every fracture is in the small diameter

parts of the piston, some have longitudinal cracks straight to the end of the small diameter, Figure 2 for the fracture of the piston of the physical picture. The working life of the

piston will directly affect the performance of the submerged hammer itself and the promotion and application of penetrating submerged hammer drilling technology, and the

reasons for its fracture should be analyzed from the special force state of the piston.

Second, the new process of submariner piston machining

Products

HFD Mining Tools is an enterprise based on independent innovation, which is committed to improving the wear resistance and service life of DTH bits and hammers.

HFD Mining Tools has successfully developed the core components of DTH hammers.

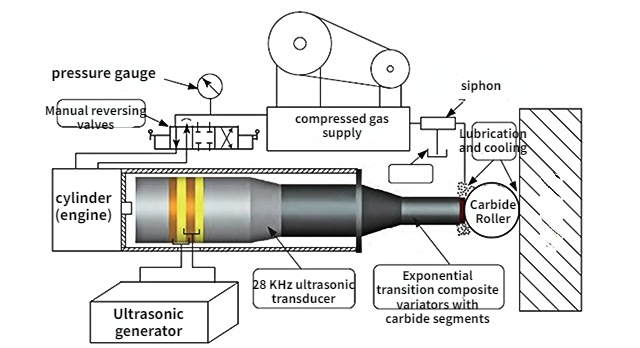

1、Product Principle

Metal surface crystal remodeling TM technology is a revolutionary innovation in metal surface processing technology from the perspective of mirror processing, crystal

remodeling, the process of research, the elimination of crystal defects on the metal surface. SPIRIT's Crystal ResurfacingTM technology can dramatically reduce surface

roughness and improve fatigue strength, microhardness, abrasion resistance, corrosion resistance and other properties of metal surfaces. It greatly improves the service

life of DTH Hammers.

2、DTH hammers piston metal surface produces six effects:

1) The metal surface can easily realize the mirror effect, Ra≤0.2μm.

2) Metal surface crystal remodeling, grain refinement.

3) Surface microhardness increased by 10%-30%.

4) Elimination of crystal defects and formation of compressive stress on the metal surface.

5) Greatly improve the wear resistance and corrosion resistance of metal surface.

6) Significantly increase the life span of the parts for relief of labor.