How should industry people choose rock drilling tools?

With the rapid development of global economic construction, the demand for rock drilling tools in engineering fields such as mining mining, energy construction, infrastructure construction and transportation road development has shown an upward trend, and higher requirements have been put forward for the quality, variety and performance of brazing tools products.

According to the types of rock drilling machinery used in geotechnical drilling projects, the supporting rock drilling brazing tools products can be roughly divided into six types: Top hammer drilling tools,Down the Hole Hammer Bits, mining turbine drilling tools, reverse patio drilling tools and geological exploration drilling tools.

Top hammer drilling tools is located at the top of the rock drilling machinery. It relies on the piston of the rock drill to directly impact the tail of the brazing tool. The impact force generated reaches the brazing head through the brazing body in the form of stress waves to complete the rock breaking. This rock drilling method uses compressed gas or hydraulic oil as the power source, and the impact power can be designed according to the requirements of the equipment, so it has a high rock drilling rate. The hole depth of this kind of drilling tool usually does not exceed 35M, and the drilling diameter does not exceed 152M. The top hammer impact rock drilling tool can generally be divided into the following categories:

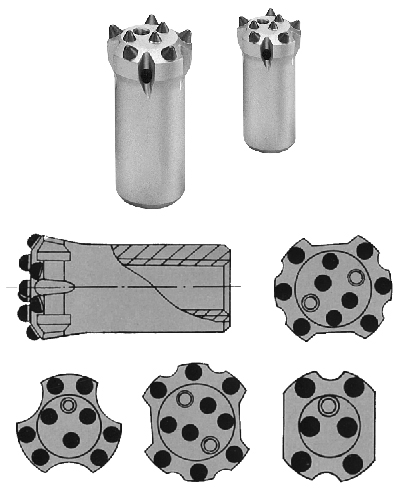

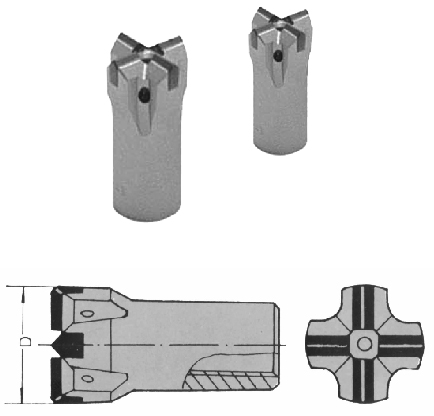

(1) Brazing tools for light rock chiseling machines. The weight of this kind of rock drilling machine is less than 35KG. It uses manual hand holding or air leg support as the working platform. The impact and propulsion of rock drilling are relatively small. Usually, the brazing tools products are H19mm and H22mm hexagonal integral brazing rods, as well as 38-42mm flat-shaped brazing heads, cross brazing heads and four-tooth and five-tooth Tapered button bit Rock Drill .

The largest light rock drilling tool products used in the domestic rock drilling engineering market are H22mm cone-linked brazing rods and flake-shaped flat-blade solder heads. Among them, Φ38-Φ43mm spherical four-tooth and five-tooth cone connection brazing head is a light rock drilling tool product developed in recent years with H22mm drill pipe. Due to its relatively stable service life and fast drilling speed in hard rock species, it has been recognized by the construction unit.

(2) Mining brazing tools for underground mining. Underground mining resources account for a large proportion of mining resources. Usually, underground mining can be divided into three forms: shallow hole rock drilling (6m), medium-hole rock drilling (pore depth 10-30m) and deep hole rock drilling (hole depth 50-60m). For holes with aperture below 43mm, H22mm cone-connected brazing rods and flat-blade, cross-shaped, or spherical-tooth brazing rods are usually used. For holes with aperture greater than 43mm, R32-H25-R32*1000m dirll pipe are used, accompanied by cross-shaped or spherical rock drilling brazing heads.