Innovative Solutions for Rock Drilling: QL DTH Hammer QL60

Application:Mining, construction, quarrying, exploration drilling, gas exploration, etc.

Customisation services: Support for customisation

Package: Wood Carton

Brand:HFD

Request a quote for detailed information (MOQ, price, delivery)

Innovative Solutions for Rock Drilling: QL DTH Hammer QL60 :

HFD's QL series DTH Hammer proven versatility and reliability make it the best choice for drilling Wells, oil and gas exploration, quarry blast holes and construction work.

We have several series of DTH hammer types, you could consider , penetration rate, reliability, air consumption, impact power,hammer life to choose the most suitable DTH hammer.

| Technical Specification: | Bit Specification: | |||

| Length(Less bit) | 1211mm |

| ||

| Weight | 105kg | |||

| Outer diameter | Φ148mm | |||

| Connection Thread | API3 1/2"REG | |||

| Bit Shank | QL60 | |||

| Hole Range | Φ158-Φ190mm | |||

| work pressure | 1.0-2.5Mpa | Splines | 12 | |

| Recommended rotation speed | 30-60 r/min | Shank Length | 253 | |

| Air Consumption | Bit Shank | QL60 | ||

| 1.0Mpa | 20m3/min | Head Diameter(mm) | Φ154-Φ203 | |

| 1.8Mpa | 28m3/min | Weight | 22.5kg-29.7kg | |

| |||||

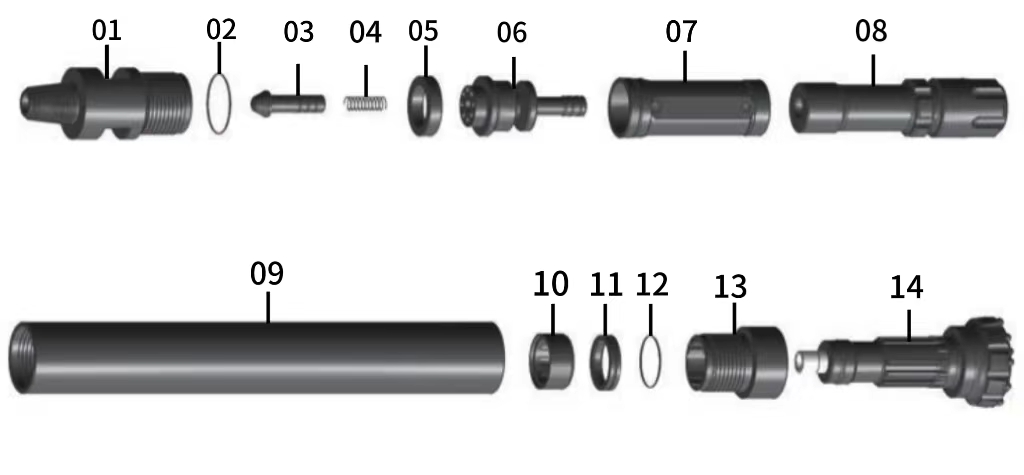

| Ref | Parts | Weight | Ref | Parts | Weight |

| 01 | Top Sub | 23Kg | 09 | Piston Case | 39Kg |

| 02 | O Ring | 0.02Kg | 10 | Guide sleeve | 1.1Kg |

| 03 | Check Valve | 0.08Kg | 11 | Retainer Ring | 0.6Kg |

| 04 | Spring | 0.05Kg | 12 | O Ring | 0.02Kg |

| 05 | Rubber Buffer | 0.3Kg | 13 | Drive Chuck | 6.3Kg |

| 06 | Valve Seat | 6.2Kg | 14 | Drill Bit | |

| 07 | lnner Cylinder | 5Kg | |||

| 08 | Piston | 23.5Kg | |||

Why Choose HFD's QL Series DTH Hammer?

1. Adopting high quality alloy steel and hardening treatment for parts to extend the service life of the submerged hammer.

2.Simple structure, reduce wear and tear between spare parts, which is easy for maintenance.

3.Adopt multiple thread to connect sub and drive chuck, which is easy for dis-assembly.

4.Adopt non-valve way of gas distribution, simple structure, easy to Disassembly, more stable.

5. With or without bottom valve. The bottom valve design helps prevent dust or water from entering the hammer, especially suitable for water well drilling or deep hole drilling. No bottom valve is required, avoiding failures caused by breakage, damage or temperature changes, and increasing productivity.

FAQ:

1. Are you exact manufacturer or just trading company?

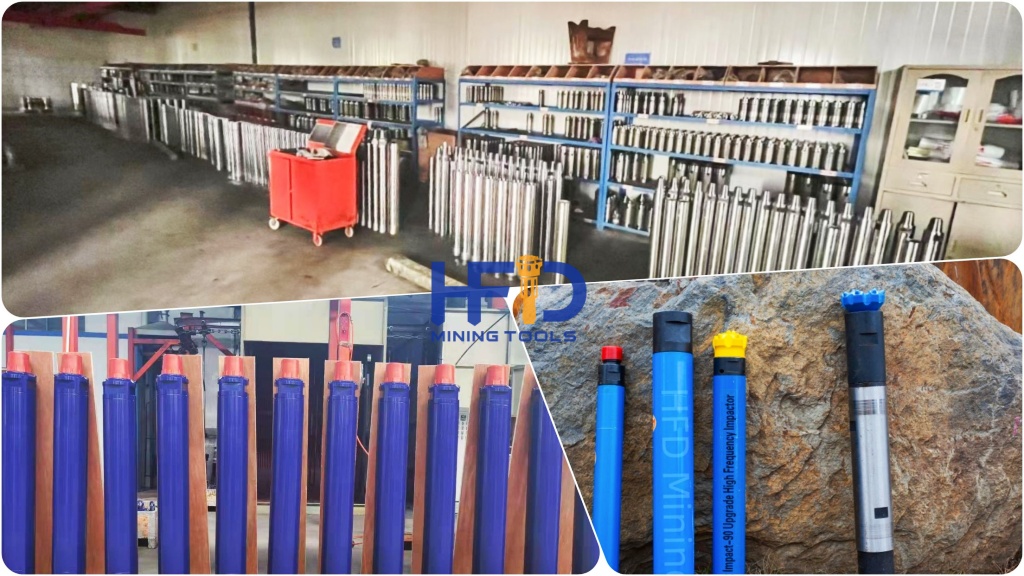

We are both,we have our own factory. And also have many long-relationship factories.

2.What is your minimum order quantity?

Our MOQ are 1pc or 1 complete set, the price may rely on the order quantity. We are welcome your sample order to testing our quality。

3. How about Packing?

Using ply-wooden cases and pallet for exporting to protect products and avoid the damagement during transportation.

Also, we can customize package according to your special requests.

4. How about the delivery time?

It depends, generally it takes about 15-25day. If have stocks, Usually only 5-10 days if in stock.

5.How to Order?

1).Pls show me which hole size do you want to drill.

2).Maybe you have a picture of it.

Related images:

HFD is available 7*24*365 all year round to provide you with operation guide and technical service at any time.