Factory Price St68 Threaded Button Drill Bit

Button shape:spherical,ballistic,parabolic Retrac,normal or straightrac

Diameter range:115mm-152mm

Rock formation:hard and abrasive

Brand: HFD Mining Tools

Request a quote for detailed information (MOQ, price, delivery)

Factory Price St68 Threaded Button Drill Bit :

The following sizes are available for you to choose from, or to provide you with customized services

| ||||||||

Diameter | No x Buttons diameter mm | Button angle° | flushing holes | Weight (Kg) | Part No | |||

mm | inch | Gauge | Front | Side | Front | |||

ST68(211/16’’)BUTTON BIT-(Spherical buttons& Ballistic buttons) | ||||||||

115 | 4 1∕2 | 8×14 | 8×12 | 35° | - | 2 | 8.2 | HD115-T68BFF8N |

127 | 5 | 8×16 | 8×14 | 35° | - | 2 | 10.2 | HD127-T68BFF8N |

140 | 5 1∕2 | 8×18 | 8×16 | 35° | - | 2 | 12.0 | HD140-T68BFF8N |

152 | 6 | 8×16 | 8×16 | 35° | - | 2 | 16.0 | HD152-T68BFF8N |

| Key features |

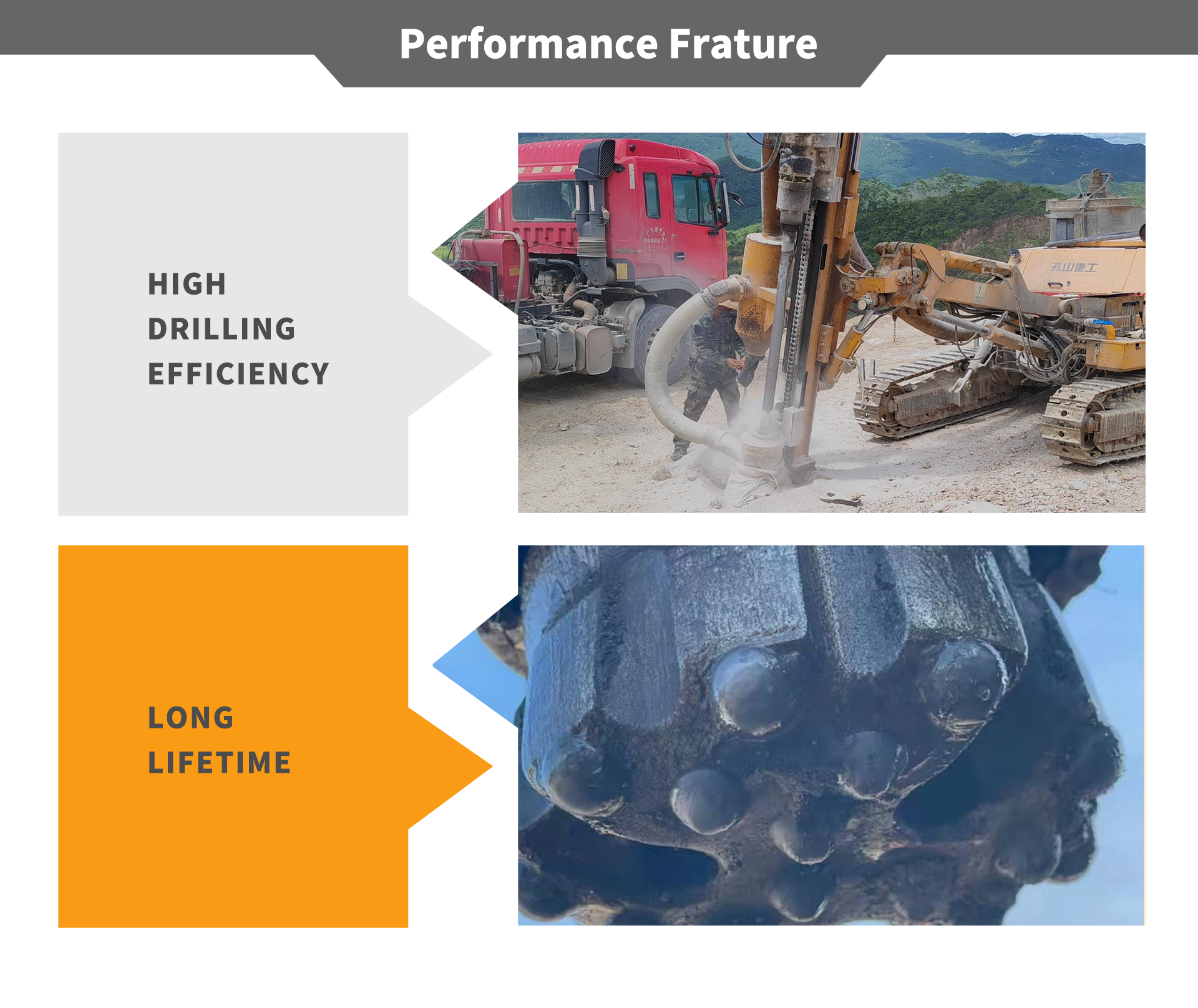

| ▲tapered button bit is a type of drill bit used in rock drilling and mining operations. It is designed with a tapered shape that allows it to easily penetrate through hard rock formations. |

▲The bit is made of quality steel and premium carbode grades. |

| ▲Process using equipment ensure the accuracy and quality of each bit. |

▲Provide difference designs to make the bit achieved the best rate of bit life and penetration rate to reduce the cost permeter. |

Why Choose HFD Down the hole bits ?

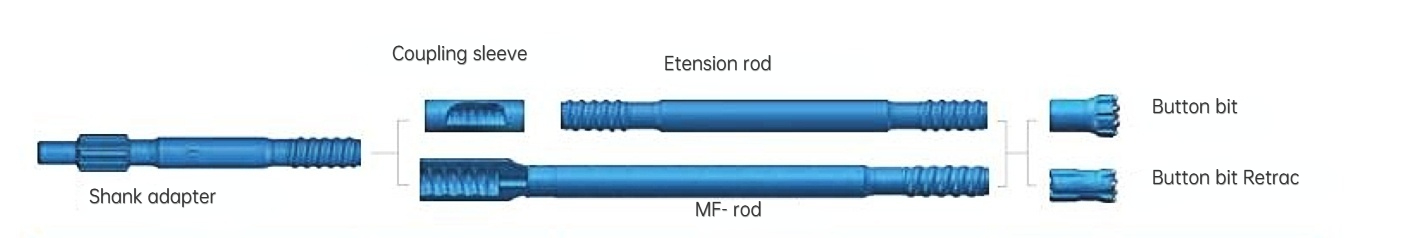

In the top hammer drilling tool manufacturing, we have world-class production technology, advanced production equipment, and experienced production technical staff. We have been working closely with our customers to conduct extensive on-site tests on various types of rocks and working conditions. Based on the feedback, we continue to improve and develop in various areas such as raw materials, heat treatment, design and manufacturing processes.

In terms of product consultation and rock tool services, we can select the most suitable rock drill tools and drilling construction schemes according to the user's construction conditions, rock type, mineral conditions and drilling equipment, so as to help users improve drilling efficiency, reduce drilling costs, and achieve better comprehensive benefits and higher labour productivity.

Our Down the hole bits have a good industry reputation in mining, tunnelling, quarrying, roads or construction due to their excellent wear resistance, roughening resistance and stability. Compared with many world-class brands of drilling tools, our rock drill tools are not inferior. In some field comparison tests, the use efficiency of our many products even exceeds that of world-class brands and has been highly recognized by customers.

Service & Support

Every purchase comes with round-the-clock after-sales service, support, and training to ensure customers get maximum productivity from their drilling operations. Having a knowledgeable and technical partner, on-site or online, can make the difference between going it alone and leveraging experience and expertise. Customers can rely on our service and support, which are provided by cost-effective and professional DTH drilling tool manufacturers. We know about downhole drilling!