The most complete knowledge of open pit mines, please miners collection

The most complete knowledge of open pit mines, please miners collection

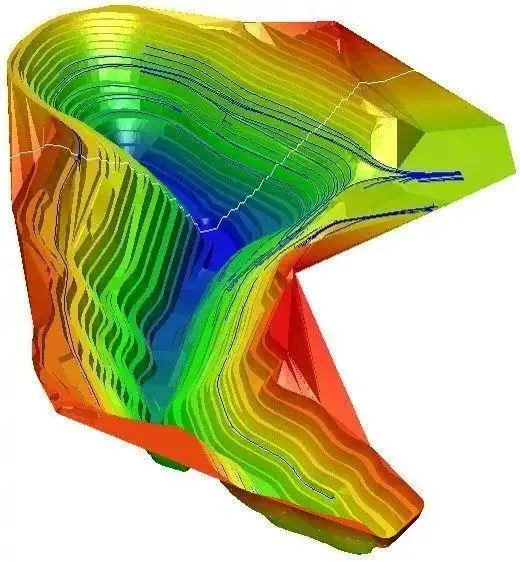

First, the composition of the three elements of the open pit mineSteps: The ore rock is divided into a certain thickness of horizontal layering,in the mining process each working level in space constitutes a step. Each step is called a step, and its height becomes the step height.

Step slope: the inclined surface of the step to the side of the mining area. The angle between the inclined surface and the horizontal plane is called the step inclination Platform (flat disk): the horizontal surface space between the bottom line and top line of the step slope.

The width between the bottom line of the slope and the top line of the slope is called the platform width , and the platform in blasting,shoveling and transportation operations is called the working platform; the width between the edge of the blasting pile and the top line of the slope is called the height of the working platform; and the platform used to intercept the sliding rock is called the safety platform.

Next, we specifically talk about the mining process of open pit miners.

Second, piercing work

Perforation work is the first process of open pit mining, and in the whole open pit mining process, the cost of perforation accounts for about 10%-15% of its total production cost.

1、Down the hole drilling rig

Down hole drilling rig drilling angle change range, high degree of mechanization, reduce the auxiliary operating time, improve the operating rate of the drilling rig, and down hole drilling rig mobile and flexible, equipment weight is light, low investment costs, especially through the drilling of a variety of slanting holes to control the ore grade, can eliminate the root of the bottom, reduce the large blocks, and improve the quality of blasting. Therefore, down hole drilling rigs are widely used in small and medium-sized mines at home and abroad, and are suitable for perforating medium and hard ore rocks.

2、tumbler drilling rig

Toothed Wheel Drilling Rig is a modern new type of drilling equipment developed on the basis of rotary drilling rig, which has the features of high perforating efficiency, low operating cost, high degree of mechanization and automation, and it is suitable for perforating various hardnesses of ore and rock, and it has become the perforating equipment commonly used in open-pit mines all over the world.

3、Rock drilling dolly

Rock Drill Trolley is a new type of rock drilling equipment which appeared with the development of mining industry. It is one or several rock drills together with automatic propellers installed in a special drilling arm or platform, and has a walking mechanism, so that the rock drill operation to achieve mechanization.

Blasting work

The purpose of blasting work is to break up the hard solid ore rock and to provide an excavation of suitable size for the mining operation. In the total cost of open pit mining, blasting costs account for about 15-20%. The quality of blasting, not only directly affect the mining, transportation, rough crushing and other equipment efficiency, but also affect the total cost of the mine.

1、shallow hole blasting

Shallow hole blasting using a small diameter of the shell hole, usually about 30-75 mm, the depth of the shell hole. Generally less than 5 meters, sometimes up to 8 meters or so, such as drilling with a rock drill dolly, the depth of the hole can be increased. Shallow hole blasting is mainly used for the production of small-scale open-pit mines or quarries, rock caving, tunnel excavation, the second burst of broken, new open-pit mine package processing, the formation of the slope of the open single-wall ditch transportation access and some other special blasting.

2、deep hole blasting

Deep hole blasting is the use of drilling equipment to drill deeper holes, as a mining explosive charge space blasting method. Deep hole blasting in open pit mines is mainly based on the production of step blasting. Deep hole blasting drilling equipment is mainly used in the application of submerged drilling and tusk drilling. Its drilling can drill vertical deep holes, but also can drill inclined holes. The loading of inclined holes is more uniform, and the blasting quality of the ore rock is better, creating good conditions for mining and loading work. In order to reduce the seismic effect and improve the quality of blasting, under certain conditions can be taken in large areas of differential blasting, loading or bottom of the air interval loading and other measures in order to reduce the cost of blasting, to achieve better economic benefits.

3、chamber blasting

Refuge blasting is a relatively large number or a large number of explosives, installed in the blasting chamber tunnel blasting method. Open-pit mines are only used in the capital construction period and under certain conditions, quarries in the conditions and in the mining demand is very large when used.

4、multi-row hole differential blasting method

In recent years, with the excavator bucket capacity and the dramatic increase in the production capacity of open-pit mines, the normal mining requirements of open-pit mines blasting each time the amount of blasting is also more and more, for this reason, domestic and foreign open-pit mining in the extensive use of multi-row holes differential blasting, multi-row holes differential blasting extrusion blasting and other large-scale blasting methods. Advantages of multi-row hole differential blasting: a large amount of blasting, reducing the number of blasts and avoiding gun time, improve the utilization rate of mining equipment Improve the crushing quality of the ore rock, the bulk rate is 40% -50% less than single-row hole blasting Improve the efficiency of perforating equipment about 10% -15%, which is due to the increase in the utilization factor of working time and perforating equipment and blasting after the reduction of the number of operations in the filling area to improve the efficiency of mining and transportation equipment about 10% -15%.

5、multi-row hole differential squeeze blasting method

Refers to the work face residual explosive pile in the case of multi-row hole differential blasting. The existence of the ballast pile, to create conditions for extrusion, on the one hand, can extend the effective time of blasting, improve the utilization of explosives and crushing effect; on the other hand, can control the width of the explosion pile, to avoid scattering of the ore rock. Multi-row hole differential squeeze blasting differential interval time than ordinary differential blasting 30% -50% appropriate, open pit mines often use 50-100ms.