Equipment Used in Slope Surface Down-The-Hole Drilling

In the field of engineering, the role of drill bits is crucial, affecting operational efficiency, safety, and costs. As a high-efficiency, safe, and cost-effective drilling equipment, HFD down-the-hole (DTH) drill bits are gradually becoming the preferred tool for engineering operations.

One of the greatest advantages of DTH Drill Bits is their efficient operational capability. In heavy-duty operations such as rock engineering and mining, time is money, and efficiency is paramount. With outstanding cutting performance and high-speed drilling technology, DTH drill bits can significantly shorten drilling time and improve drilling efficiency. This not only helps shorten the project duration and reduce labor costs but also enhances the economic benefits for enterprises.

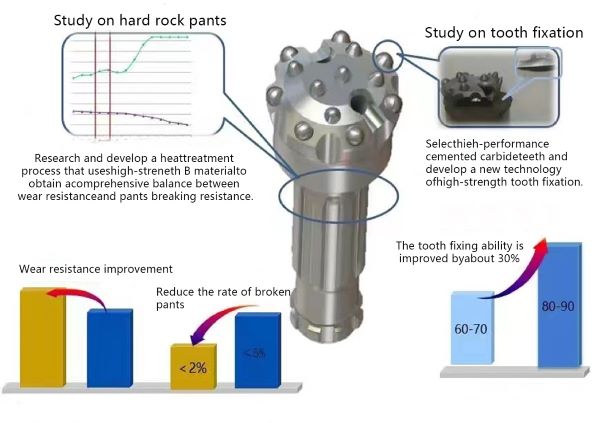

Furthermore, the safety and reliability of DTH drill bits are another important reason for their popularity. Safety is always the primary consideration in engineering operations. DTH drill bits are made of high-quality materials and precision manufacturing processes, ensuring high stability and reliability during use. These high manufacturing standards reduce the possibility of failures and accidents, providing operators with an additional layer of safety assurance. Moreover, the design of DTH drill bits fully considers operational convenience and comfort, further enhancing operational safety.

Lastly, the economic savings of DTH drill bits are also significant advantages. Due to their long service life, they can reduce the cost of frequent bit replacements. Additionally, the high operational efficiency of DTH drill bits can save a considerable amount of manpower and material resources for engineering projects. In the fierce market competition, these cost-saving advantages bring greater economic benefits and competitive advantages to enterprises.